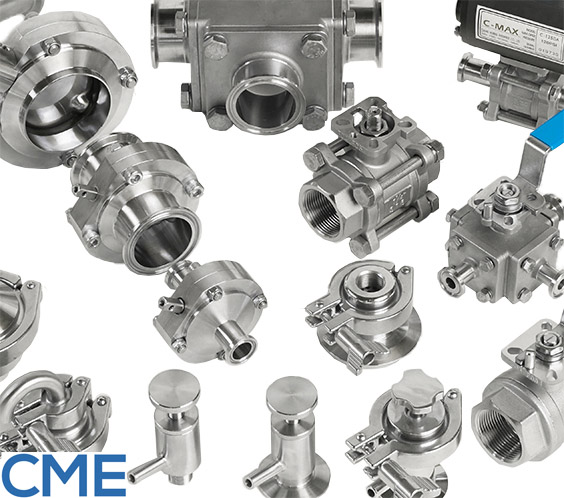

Sanitary Valves

Sanitary Butterfly Valve

Sanitary Valves Series

The sanitary butterfly valve can be operated manually by handles or automatically through actuators.

CME offers the sanitary butterfly valve with below advantage.

1. Sanitary butterfly valve size from ½” to 8”.

2. Forged 316L on disc and bodies.

3. Three different seal options from AVK GUMMI A/S, including Silicone, EPDM, and FKM.

4. Various manual or automatic operators available.

5. All rubber materials are FDA compliance and have tested over 10,000 cycles in 5% alcohol under 2oC.

6. 100% tested and inspected on each sanitary butterfly valve.

7. All wetted surface are sanitary finish.

Sanitary Ball Valve

Sanitary Valves Series

Sanitary ball valves are also known as hygienic ball valve, which mainly used in the food and beverage industry.

Sanitary ball vales features and benefits:

1. Sanitary ball valve size from 1/2" to 4".

2. Full port design offers lower pressure drop and a less turbulent flow.

3. ISO5211 mounting pad as standard for easy assembly with different type of actuators.

4. Pressure rating: 1/2" - 2" 1000PSO WOG; 2 1/2" - 4" 800PSI WOG.

5. All wetted surface are sanitary finish.

6. Five different seat materials for all applications.

7. 100% tested and inspected on each sanitary ball valve.

Industrial Ball Valve

Sanitary Valves Series

The industrial ball valve is manufactured of CF8M.

CME offers the 3-piece industrial ball valve with FNPT and socket weld ends with below features.

1. Industrial ball valve size from 1/2" to 4".

2. Full port design.

3. ISO 5211 high mounting pad as standard.

4. Pressure rating: 1/2" - 2" 1000PSI WOG; 2 1/2" - 3" 800PSI WOG; 4" 600 PSI WOG.

5. 100% tested and inspected on each industrial ball valve.

Sanitary Sampling Valve

Sanitary Valves Series

Sanitary sampling valves has always been widely used in the wineries. CME offers the sanitary sample valves in different connections with below advantages.

1. Sanitary sampling valves size available from 3/8" to 2".

2. Material 304 and 316L Stainless steel.

3. Double silicone O-rings.

4. Silicone or PTFE seat ensures a leak-proof shut-off.

5. All wetted surface are sanitary finish.

6. Pressure rating: 200 PSI.

7. Temperature Rating: 300°F.

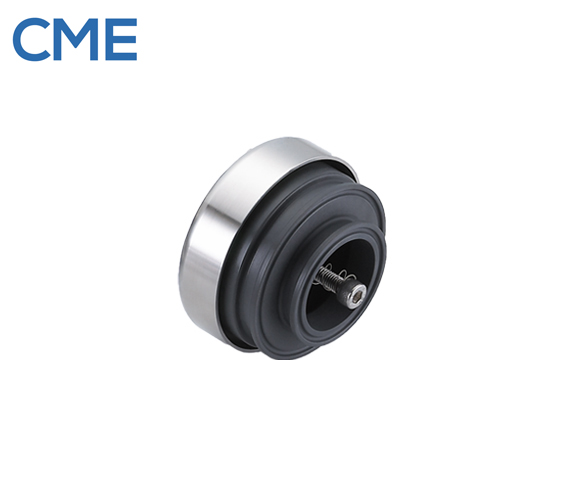

Sanitary Y-Ball Check Valve

Sanitary Valves Series

Sanitary Y-ball check valve are used where full flow and low pressure drop of product during process. When the flow stops, the PTFE ball rolls back and seats to prevent backflow. The two-piece design of sanitary Y-ball check valves are available from sizes 11/2" to 3".

Sanitary Y-ball check valve Features and Benefits

1. Sizes from 1 1/2" to 3"

2. Two- piece design for better alignment.

3. All wetted surface are sanitary finish in 316L stainless steel.

4. PTFE ball provides a better heat and abrasion resistance.

5. Repair kits are available for seat replacement.

6. Easy cleaning without tools.

7. Air blow check valve can be added.

8. Maximum operating pressure: 150 PSI.

9. Operating temperature range: -15°F to 200°F